- Establish an optimal communication system through connection to Heterogeneous System (Configure Communication Loop)

- Discover new values of production such as monitoring, process analysis, logistics flow with connection to Heterogeneous System

- Forward to flexible production for seamless connection that enables rapid conversion of physical set-up and direction during mixed production.

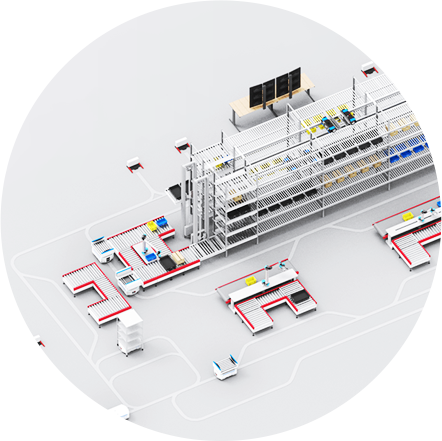

Smart Factory

Smart Factory make possible continuous production

Without wasting resources and time with specialized warehouse management system

Without wasting resources and time with specialized warehouse management system

CSC 1.0

Work-In-Process Handling

One Connected Process

We reduce time and labor with connection to data and control integration of Heterogeneous System

CSC 2.0

Storage, Buffering, Replenishment

Minimumized Distance

Minimumized Space

Minimumized Space

We can reduce manufacturing cost, error and defect rates with efficiently improve to individual process. It makes high quality and increased productivity.

- Loadspace efficiency maximized, fast speed, box fittings of various sizes, flexible rack expansion, energy saving, easy maintenance

- Build complete portfolio of manufacturing applications

CSC 3.0

Automatic Fulfillment System

Automatically Movement

TAGON

TAGON

TAGON is transport robot system that can transport tray from warehouse in automatically

- Efficient inventory management and warehouse operation through WMS

- Easy management to inventory level layout status, storage capacity by location, efficient prepare for changes in volume

- Applicable to all industries: machining, injection, assembly, manufacturing, and production

- Minimize gap between aisle space and rack to maximize storage efficiency

- Free mobility with QR code awareness and flexible and easy warehouse scalability

- Minimize downtime with fast charging

Carrier Robot

Increase the efficiency of logistics

TAGON AGV

TAGON AGV

It automatically transfer all forms of logistics units such as container, carton box, cart, rack, pallet, etc. safely and precisely. It makes production without down time and maximizes logistics efficiency.

Automatically movement

TAGON Shuttle

TAGON Shuttle

TAGON Shuttle is to transport supplies, following rail between racks. Single or double-deep picking/loading is available, and positioning is to be done by reading coordinates of 2D-code at the side of rail. As shuttle system is connected to WMS and automation system such as lifter and shuttle lifter, throughput and warehouse turnover can be maximized.