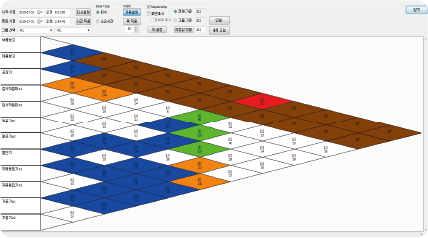

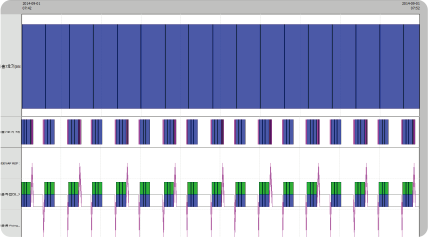

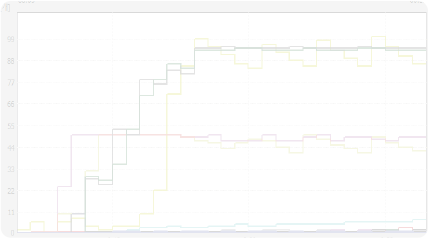

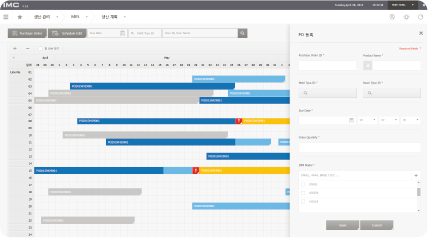

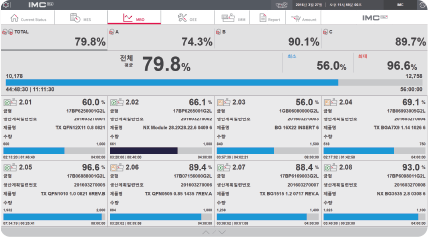

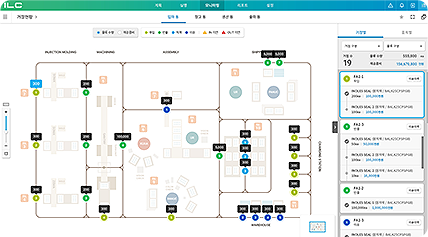

implements cyber manufacturing by reproducing

actual physical space into 3D cyber space.

It helps to choose the optimum alternative option

after conducting simulation with various

production conditions and comparing results

based on high predictability.

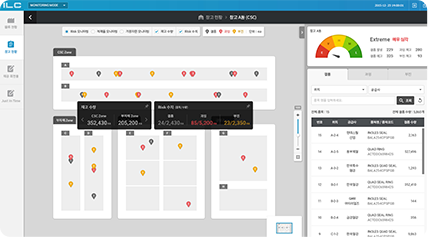

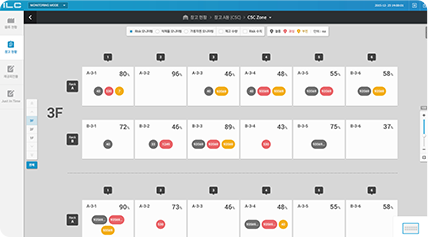

- To verify new plants or processing line

- To improve the current process and analyze efficiency