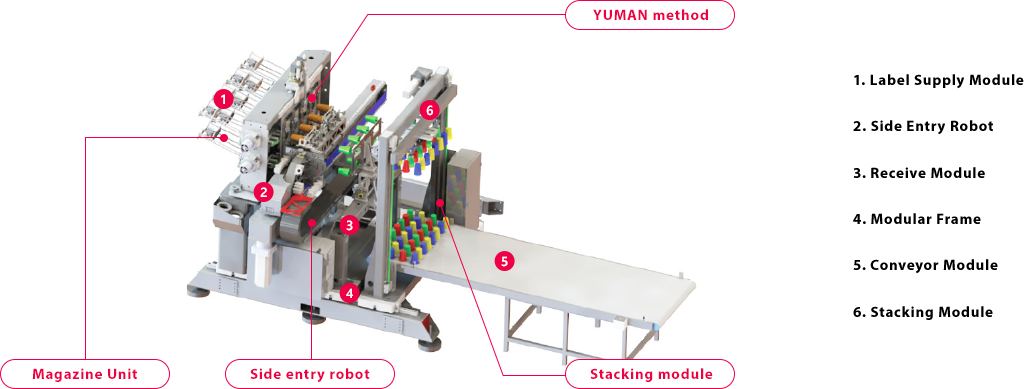

In-Mold Labeling Technology

FOR PROCESS INNOVATION & QUALITY IMPROVEMENT

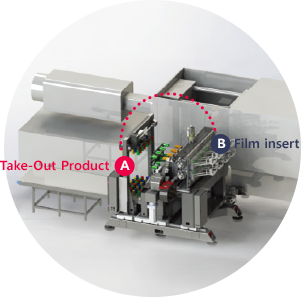

The IML system is designed to support the use of key instruments such as side entry robots,

film suppliers, and load/conveying systems. Modular system configuration enables rapid and precise implementation of complex processes of IML injection

FLEX Module

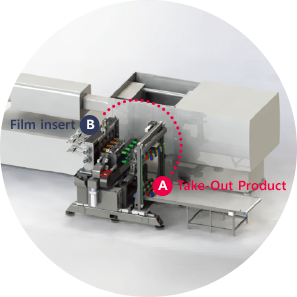

FLEX MODULE can vary the IML production process at any time depending on the demand of the product.

Accelerate production of consistent, high-quality products with state-of-the-art motion controls and proven instrument performance.

This flexible production process and just-in-time enables the best IML injection solution for productivity gains

Depending on the mold structure, major module instruments can be reasonably reconfigured and

additional modules can be installed for inspection and assembly other than basic instrument configurations.

This not only reduces the cost of facility investment, but also reduces the reset time due to component modification.

Combination of FLEX Module

Cup & Container IML

Lid IML